About

- Armacam

- About

We are a specialized engineering and manufacturing company focused on delivering complete solutions in tool design and CNC machining. Our mission is to provide high-quality, reliable, and cost-effective services tailored to the needs of modern industry.

Based in Sarajevo, Bosnia and Herzegovina, our team includes experienced mechanical engineers, CAD designers, and CNC technicians dedicated to precision and performance.

We maintain close collaborations with leading international partners to ensure continuous improvement, innovation, and excellence.

Tool Design & Engineering

-3D CAD design progressive and transfer tools in the car industry

-Process simulation and method planning

-Prototyping and serial tool manufacturing

-Expertise in exterior and interior automotive components

-Full support from concept to production-ready tooling

CNC Machining

-High-precision CNC milling and turning

-Production of metal parts for various industries

-Tight tolerances and a wide range of materials

-Flexible batch sizes (small to serial production)

-Surface finishing and quality control procedures

Automatic horizontal band saw HBA220

The HBA220 is an automatic horizontal band saw designed for fast and accurate cutting of metal materials.

It handles diameters up to 220 mm, with a 3280 mm long and 27 mm wide saw band.

Suitable for flat (220 × 150 mm) and square (190 × 190 mm) profiles, it's ideal for daily use and small-to-medium batch production.

Puma 300 MS with Loader LMS

The Puma 300 MS is a high-performance CNC turning center equipped with an automatic bar feeder (loader LMS), designed for efficient multitasking in serial production.

With a maximum turning diameter of 355 mm and a turning length of 583 mm, it offers extended flexibility for complex part geometries. The machine features a 12-station turret, powerful main spindle at 3500 rpm, and a sub-spindle reaching 4500 rpm, enabling simultaneous operations and reduced cycle times.

Ideal for high-precision machining, this machine ensures accuracy, productivity, and reliability in demanding industrial environments.

Puma 2000 SY

The Puma 2000 SY is a high-precision multi-axis CNC lathe designed for complex part machining.

It offers a max turning diameter of 330 mm and turning length of 760 mm, with axis travels of X: 250 mm, Z: 830 mm, Y: 100 mm, and B: 830 mm.

The machine features a 12-station turret, a main spindle speed of 4500 rpm, and a sub-spindle speed of 6000 rpm, allowing for efficient dual-spindle operations and reduced cycle times.

An ideal solution for manufacturers requiring versatility, accuracy, and productivity in one system.

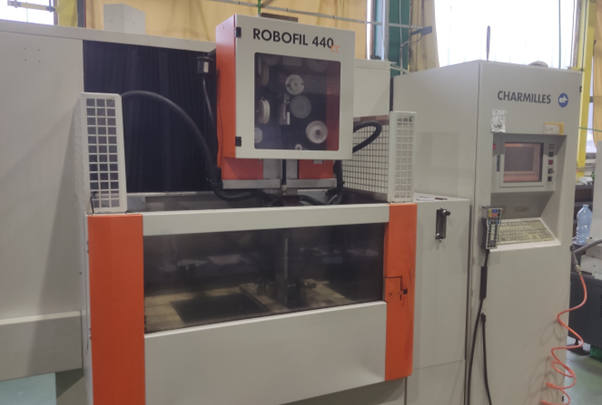

Robofil 440 EDM Machining Center

The Robofil 440 is a high-precision EDM (Electrical Discharge Machining) wire cutting center designed for complex part geometries and fine tolerances.

It supports workpieces up to 1500 kg with maximum dimensions of 1250 × 750 mm and a submerged cutting height of 400 mm.

The machine features X/Y travel of 550 × 350 mm, UV travel of 550 × 350 mm, and a Z-axis travel up to 400 mm, offering excellent flexibility for multi-axis contouring.

Its programmable wire circuit includes speeds from 0.5 to 15 m/min, tension from 3 to 25 N, and supports threading holes as small as 0.6 mm, making it ideal for fine-detail machining.

VM-3 Vertical Machining Center

The VM-3 is a high-performance vertical machining center built for precision milling, drilling, and tapping applications.

It offers large travel capacities of X: 1016 mm, Y: 660 mm, and Z: 635 mm, making it ideal for medium to large workpieces.

The table measures 1372 × 635 mm, with 16 mm T-slots and 100 mm center spacing, providing excellent clamping flexibility.

Its powerful 22.4 kW spindle reaches speeds up to 12,000 rpm, delivering a maximum torque of 90 ft-lb at 2000 rpm — perfect for high-speed machining and heavy material removal.

Haas VF-2SS – Super-Speed Vertical Machining Center

The VF-2SS is a high-speed vertical machining center designed for maximum efficiency in precision milling applications.

With travel dimensions of X: 762 mm, Y: 406 mm, and Z: 508 mm, it handles medium-size parts with ease.

Its inline direct-drive spindle delivers up to 22.4 kW, 12,000 rpm, and 122 Nm torque at 2000 rpm, ensuring excellent cutting performance.

Equipped with liquid cooling, air/oil bearing lubrication, and support for CT40, BT40, or HSK-A63 tapers, it is built for reliability and speed.

The worktable measures 914 × 356 mm, with T-slot widths between 15.90–16.00 mm, and a 125 mm center distance, offering strong versatility in fixture setup.